Worm Gear: What Is It? How Is it Made? Types Of, Uses

Table of Content

The least complicated worm gears are those that are used to tune stringed instruments. Placed on the head of the instrument, the worm gear allows for easy tuning and adjustments to raise or lower the pitch of a string. A split mounting is similar to a set screw mounting but requires the use of screws and a clamp. The type of clamp varies, but all have a hole that fits over the hub of the worm gear. The hub is split or notched such that when the clamp is placed over it and tightened then separated, spread pieces are squeezed together to secure the hub.

The shop I got it from NEVER cleaned anything and the table was VERY stiff from accumulated black tar like junk. When I looked at the machine, I was amazed at how filthy it looked, but how little wear there was on everything that I checked. Oh, if I didn’t make it clear, this is for a prototype. Once my design is finalized and initially tested, I’d have someone bulk produce the needed bespoke gears out of something suitable like hardened steel or whatever is appropriate.

About Community

For the prototype it just needs to demonstrate function to me. This is all “man powered” btw, which is to say the worm gear will be turned via a hand crank, not a high torque motor or anything. The amount of stress, torque, and motion worm gears deal with requires the use of lubricants to provide good lubricity in metal to metal contact. Mineral based lubricants are commonly used with worm gears; they are made from mineral oil, a product of crude oil. The goal of a worm gear lubricant is to protect the worm drive from friction, corrosion, and inefficiency.

You will notice the increase in their population and accumulation of worm castings. Assuming that you have already decided on the location of the worm farm, it is time to stack them up. There are various species of worms, but you can’t just use any random species of worms for composting. Now that you have figured out the type, size, placement, and harvest method for your worm farm, let’s gather the items required for this DIY project. It’s worth considering the placement and space available for setting up the worm farm. Once you have set up your worm farm, you can just sit back and relax.

Indoor Worm Bins or Outdoor Worm Bins?

I saw earlier it was only for solidworks and could not figure out the math to use the demo so I am happy to see fusion 360 support. Click More in the right lower corner of the Design tab to open the More Options area, where you can select other options for your calculation. We recommend that you select both cylindrical faces because gears are automatically put together. Use the tap on the bottom sump bin to drain off the worm tea every few weeks.

Speed reduction is determined by the number of worm threads and the number of teeth on the worm wheel. Though there are steel worm gears and worm wheels, the usual configuration is a steel worm gear with a bronze or brass worm wheel. Steel is used for its durability, tensile strength, and longevity.

Get Your Company Listed on this Power Page

A place for the discussion of all manner of metal casting and foundry work, whether in the backyard or on a commercial scale.

Assembly with the Design Accelerator worm gear already inserted. You can put fruit and veggie scraps, but unlike compost bins, you need to exclude citrus and onions as worms don’t like them. Worm farms also take egg shells, cartons, newspaper, tea leaves and bread.

The infeed X is set to the proper depth with a vertical feed rate Z and a lateral shifting motion Y that shifts the abrasive worm a small amount for the vertical feed rate. A worm gear is the most compact type of gearing system. They are capable of being placed in very small spaces and still providing high ratio speed reduction.

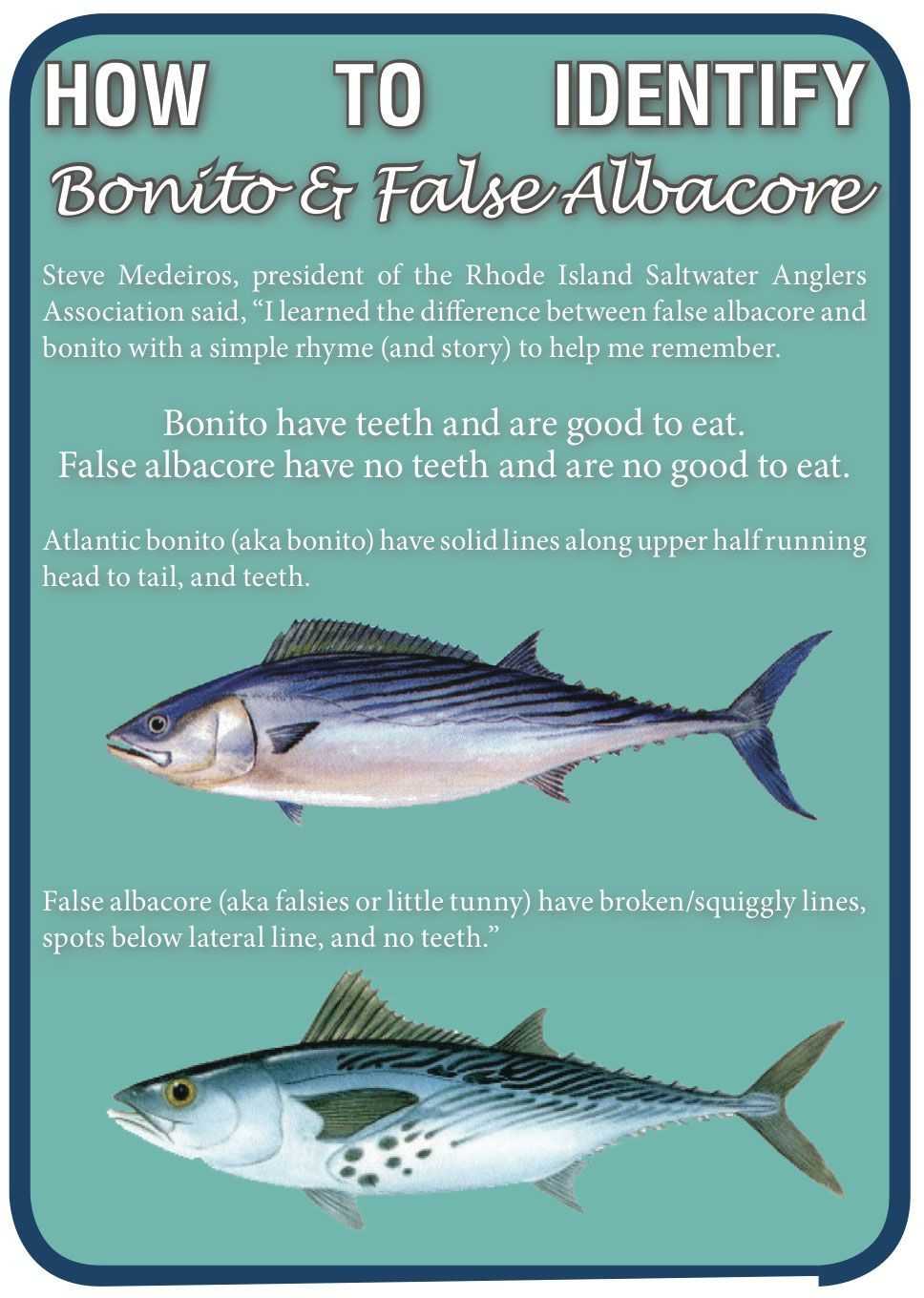

Non-throated worm gears are designed to handle small loads and are easy to make. The difference between single throat worm gears and double throat types is their shape. Double throat worm gears are concave on the gear and worm screw. The teeth of the gear and the shape of the worm threads are designed to increase the contact between the wheel and worm.

Worm farms are great for people with smaller gardens or no gardens as they take food scraps only. With worm farms, you’ll need to regularly feed your worms with food scraps, and they will in turn give you worm castings to use in the garden. The two basic types of worm gears are cylindrical or straight and cone or double enveloping. The faces of worm gears are broken into straight, hobbed, and concave. Apparently these Rockwells will “eat” that worm gear if you let the carriage get “too stiff” and use the power feeds much.

A single throated worm gear has incurvate helical teeth designed around the worm for a contact line. This type of worm gear can withstand higher power without additional wear. In this type of worm gear, only one set of threads on the worm make contact with the worm wheel. Due to the fact that there is single contact, which produces significant friction, the worm has to be much harder and stronger than the wheel. A worm gear is a staggered shaft gear that creates motion between shafts using threads that are cut into a cylindrical bar to provide speed reduction. The combination of a worm wheel and worm are the components of a worm gear.

With proper mounting and installation, worm gear systems operate smoothly and quietly. The advantages of worm gears include noise and vibration reduction as well as compactness. They are made of hardened metals because of the amount of heat they generate. Rotate the bins after each harvesting so that the worms can migrate to another container and you can easily harvest worm castings from your worm composting efforts.

The steel worm gear and steel worm wheel combination are more expensive and require extensive time and effort to repair when they fail. A gearbox is used to change the torque or output speed of a motor. A worm gearbox has the basic design of a worm with a threaded worm gear shaft and a wheel gear. As the worm gear rotates against the worm wheel, a load is rotated by the worm wheel. Double throat worm gears are able to handle high loads. The design of the double throat provides the tightest connection between the worm and the gear.

Comments

Post a Comment